How Tube Filling Machine Alignment Affects Your Bottom Line – And How to Fix It

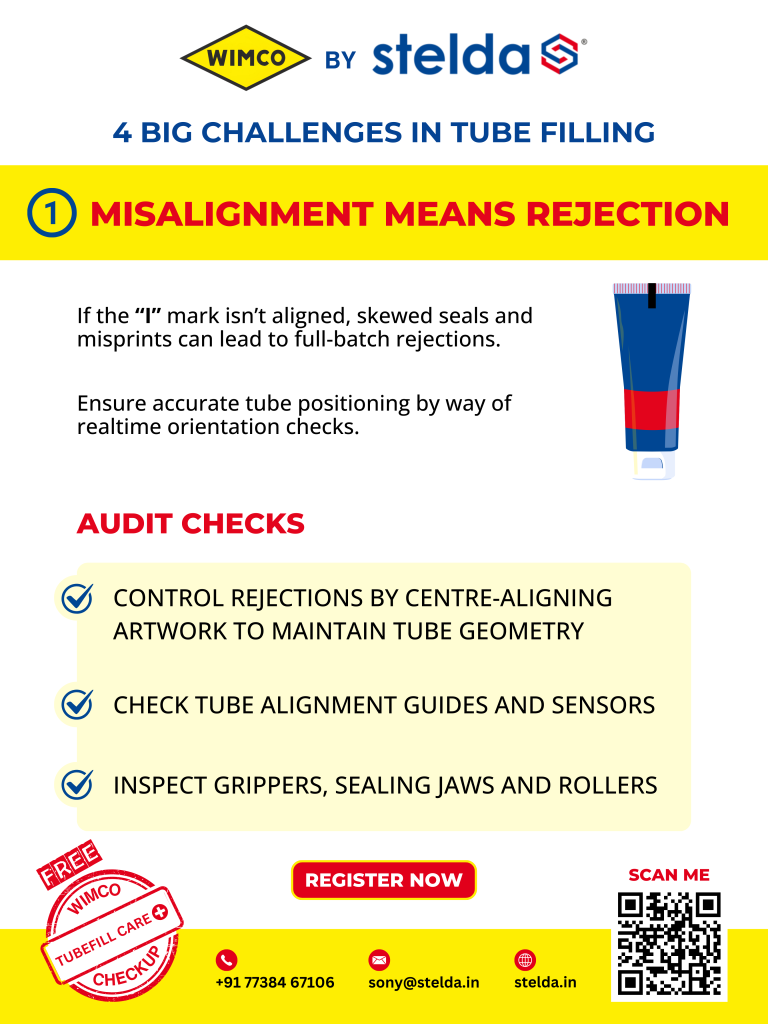

Did you know? A misaligned tube filling machine can cause up to a 15% increase in product waste, disrupt seal integrity, and lead to regulatory non-compliance in industries like pharmaceuticals and cosmetics.

Tube filling machine alignment isn’t just about aesthetics—it’s a fundamental factor in ensuring operational efficiency, product quality, and compliance. A minor misalignment can:

✔ Reduce filling precision, causing overfilled or underfilled tubes.

✔ Compromise seals, leading to leaks and contamination risks.

✔ Slow down production, forcing operators to make constant manual adjustments.

✔ Cause rejection of final products, impacting your bottom line.

In this guide, we’ll break down the causes, impact, and solutions for tube filling machine alignment issues and provide a technical, in-depth troubleshooting checklist.

Why Tube Filling Machine Alignment Matters

In pharmaceutical, cosmetic, and food manufacturing, tube filling involves precise operations:

- Tube Orientation: Tubes must be properly positioned before entering the filling station.

- Filling Accuracy: The product must be dispensed centrally without excess residue.

- Sealing Precision: The tube must align exactly with the sealing jaws to ensure an airtight, tamper-proof seal.

Even 0.5mm misalignment can lead to product defects, making tube filling machine alignment a critical factor in maintaining industry standards like:

- GMP (Good Manufacturing Practices)

- FDA Regulations for Pharmaceuticals & Cosmetics

- ISO 9001 Manufacturing Standards

Common Causes of Tube Filling Machine Misalignment

1. Inconsistent Tube Feeding Mechanism

- What happens?

- Tubes enter the filling system at an incorrect angle, leading to improper positioning at the filling station.

- The tube clamp mechanism fails to hold tubes securely, causing shifts during the fill cycle.

- Solution:

✅ Ensure the tube loading carousel is calibrated to match tube dimensions.

✅ Inspect gripping mechanisms for wear and replace faulty clamps.

2. Calibration Errors in Sensor Systems

- What happens?

- Optical and mechanical sensors misread tube positions, leading to misalignment errors in high-speed production.

- Inconsistent fill levels due to incorrect sensor detection.

- Solution:

✅ Conduct automated sensor recalibration weekly.

✅ Use AI-powered detection to optimize real-time tube positioning.

3. Worn-Out Tube Positioning Mechanisms

- What happens?

- Mechanical guides, clamps, and rotary plates degrade over time, causing minor shifts that disrupt tube alignment consistency.

- Solution:

✅ Replace grippers, servo motors, and guide rails at predefined maintenance intervals.

✅ Switch to servo-driven tube positioning systems for enhanced precision.

4. Vibration and External Disturbances

- What happens?

- Factory vibrations or unstable floor mounting can slightly alter alignment precision, especially in high-speed fillers.

- Solution:

✅ Secure the machine with anti-vibration mounts.

✅ Use real-time torque monitoring for rotary components.

Troubleshooting Tube Filling Machine Alignment Issues

Step 1: Check Tube Orientation Before Filling

🔍 Inspect the tube carousel – are tubes aligned correctly before entering the filling station?

🔍 Adjust tube holders – confirm they grip tubes firmly but not too tightly to prevent shifting.

Step 2: Validate Nozzle-to-Tube Alignment

🔍 Measure fill accuracy – a variance of more than ±1% indicates alignment drift.

🔍 Check nozzle travel path – ensure it lowers precisely into the tube’s center.

Step 3: Analyze Seal Integrity & Tube Position

🔍 Evaluate crimping/sealing mechanisms – heat jaws or ultrasonic sealing heads must be centered for airtight seals.

🔍 Inspect tube rotation – slight tube movement during sealing can cause defective seals.

7 Advanced Strategies to Maintain Tube Filling Machine Alignment

1. Upgrade to Servo-Controlled Tube Alignment Systems

📌 Why? Traditional pneumatic systems cause slight variations in tube positioning. Servo systems ensure high-precision alignment.

2. Use High-Resolution Camera Sensors for Tube Orientation

📌 Why? AI-powered cameras can detect misalignment in real time and automatically adjust tube positioning.

3. Implement Automatic Recalibration Software

📌 Why? Auto-calibration systems self-adjust mechanical offsets, reducing manual intervention.

4. Adopt Predictive Maintenance for Positioning Mechanisms

📌 Why? AI-based maintenance systems detect wear in alignment guides before failure.

5. Optimize Tube Loading & Conveyor Synchronization

📌 Why? Poor conveyor-to-feeder synchronization distorts tube orientation before filling.

6. Adjust Machine Mounting for Maximum Stability

📌 Why? Unstable machine bases affect precision, especially at higher production speeds.

7. Leverage Smart AI Feedback for Operator Training

📌 Why? AI-guided machine learning algorithms help operators detect early alignment issues.

Maximizing Efficiency with Precision Tube Filling Machine Alignment

A perfectly aligned tube filling machine leads to:

✅ Higher production efficiency – reduced rejections and faster cycles.

✅ Minimal product wastage – precise alignment ensures accurate fills.

✅ Stronger brand reputation – visually perfect, defect-free packaging.

🚀 The future of tube filling is precision-driven! By leveraging advanced alignment systems, AI detection, and servo-controlled mechanisms, manufacturers can eliminate inefficiencies and boost overall output.

💡 Want expert alignment solutions? Contact us today for precision engineering upgrades!📢 Follow us on LinkedIn, Facebook & YouTube for more manufacturing insights!