Did you know? According to a study by the Ponemon Institute, companies lose an average of 2% of their inventory due to pilferage in their B2B supply chain. This number can vary depending on the industry, but it is clear that pilferage is a significant problem for businesses.

The most common types of products pilfered in the B2B supply chain include:

Food and beverages: This is the most common type of product pilfered, accounting for over 30% of all pilferage losses.

Pharmaceuticals: Pharmaceuticals are also a popular target for pilferers, as they are often high-value and easy to sell on the black market.

Electronics: Electronics are another popular target for pilferers, as they are often high-value and easy to conceal.

Clothing: Clothing is also a popular target for pilferers, as it is often easy to sell on the black market or online.

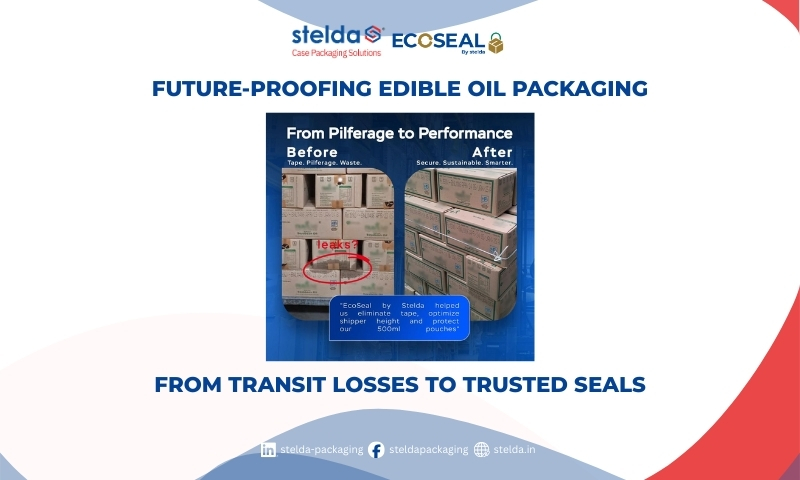

Driven by thorough research and resource utilisation, we have successfully developed machines that package shipper cartons with tamper-evident features, paving the way for a comprehensive solution to this problem.

By pioneering a glue-sealing alternative that eliminates the need for plastic tapes, straps, and shrink wraps, Stelda significantly enhances operational efficiency and environmental sustainability. This innovative approach reduces business costs, pilferage losses, and damage rates by over 30%, contributing to a robust safety agenda across industries. With its mission to make shipper carton packaging stronger, secure, sustainable and cost-effective, aspires to change the way packaging is perceived in the current supply chain. But before we go there, let’s start with some background.

How huge is pilferage a challenge for Manufacturers?

Countries like India and China compete to become the world’s manufacturing hub. But, one problem went unnoticed: shipping the manufacturing material to stores/ franchises/ places of purchase. And not just shipping, but shipping it in a manner that it reaches every point on the supply chain tamper-free. We studied the supply chain used by manufacturing companies to ship their products to their stores/franchises or points of sale and unearthed some surprising challenges.

A study by the supply chain council found that 75% of the supply chain managers agreed that pilferage is a significant problem for them. And BOPP tapes cannot deter pilferage, as they are easy to remove and replace. But how can we solve it?

Detecting product pilferage and switching to solutions that offer exclusive tamper evidence can be the go-to solution here.

How would Tamper evident packaging help you with a pilferage-free supply chain?

Tamper-evident packaging is created in a manner that once opened, it is difficult to reseal the carton as there will be fiber tear. Tamper evident packaging helps verify at every point, whether they received the carton in a packed or tempered manner. This certainly helps in shipments of products, specially the fragile and the most expensive ones. With rising thefts during the transit of goods, tracing the source of pilferage is vital.

Filing complaints after final delivery doesn’t always help. One may also counter the complaint with an argument as an effort to make up for the losses from damaged shipments. That’s where Tamper-evident packaging plays a vital role.

What Is Tamper-evident Packaging?

Tamper-evident packaging includes the usage of devices or methods that leave signs of manipulation in case of any attempt at tampering. Security seals used in tamper-evident packaging are a barrier to the pilferage attempt of the shipper cartons.

Why should businesses shift to Tamper-Evident Packaging?

Eliminate the risk of damaged goods

Tamper-evident packaging is the best way to safeguard the products while restricting the boxes from being opened during shipment. This helps in mitigating redundant revenue losses, creating a superior brand image. Moreover, tamper-evident packaging suits safety packaging requirements for diverse industries while indulging in various practices.

Trending best industry practices involved in tamper-evident packaging

Tamper-evident packaging can be divided into four categories:

- Chemical blockade: This range is usually made of materials such as hot glue and wax. This blockade makes it hard to open whenever touched or tried to break. When opened, it quickly leaves back evidence of the damaged shipment.

- Physical blockade: This includes blocking with materials such as metal or plastic, which cannot be opened without using tools like scissors or knives. A few businesses also use reinforced gummed tape for tamper-evident packaging. This tape can be opened only with a sharp object pierced into its fiberglass thread. Businesses nowadays are also inclined towards RFID in labelling and ink-coding.

- Mechanical blockade: This includes materials such as wires or metal clasps to hold the items inside the package tightly, making it difficult to open.

- Electronic blockade: Not very commonly used, this range comprises wireless signals for anyone to request permission without opening the package.

A business can choose the type of blockade that best suits its product packaging. However, other aspects play an essential part in reducing pilferage. Stelda case sealing solution is an illustration of chemical blockade with the use of hot melt adhesive instead of taping. This hot melt adhesive seals cause the fiber to tear if an attempt to open the case before it reaches its destination. With this, it provides superior tamper-evidence and product protection.

Additional points you can do to avoid pilferage

Must have staff background checks and set pilferage policies

Conducting background checks on employees and contractors handling packages helps identify individuals with a history of theft or criminal activity. By explaining the legal consequences of theft or tampering with packages, businesses must create awareness among the staff members.

Monitor location via GPS tracking

Tracking packages in real-time can help to identify any deviations during the shipping process. It could be anything, such as unwanted stops, delays, or incorrect routes. Extra precautions on these routes can save businesses from theft and loss.

Share restricted shipper carton access to staff

Restricting access to specifically authorised personnel limits the number of people to pursue the shipper cartons. Businesses can do this by storing containers securely with tight safety measures.

Protect shipper cartons by insuring them

Insuring shipments can help protect them against losses due to theft or damage. Businesses can be at peace of mind by not worrying about pilfers, saving more time, and focusing on faster growth.

Conclusion

Overall, here is a clear brief of how tamper-evident packaging can help you boost your business growth.

- Increased package strength and security – This cannot be opened without breaking the seal/ glued area. Any effort to break the holt melt adhesive tears the fibre, rendering resealing problematic and definitively exposing tampering.

- Reduced Material Waste – Hot melt adhesives can provide the security offered by straps or films against pilferage. These hotmelts stick to the corrugated board and get separated during the recycling process, leaving no scope of littering or wastage.

- Reduced package theft in transit

- Recyclable, biodegradable = sustainable usage

It’s time to switch to the best-in-class, sustainable, tamper-evident packaging practices without compromising your budget and business growth.