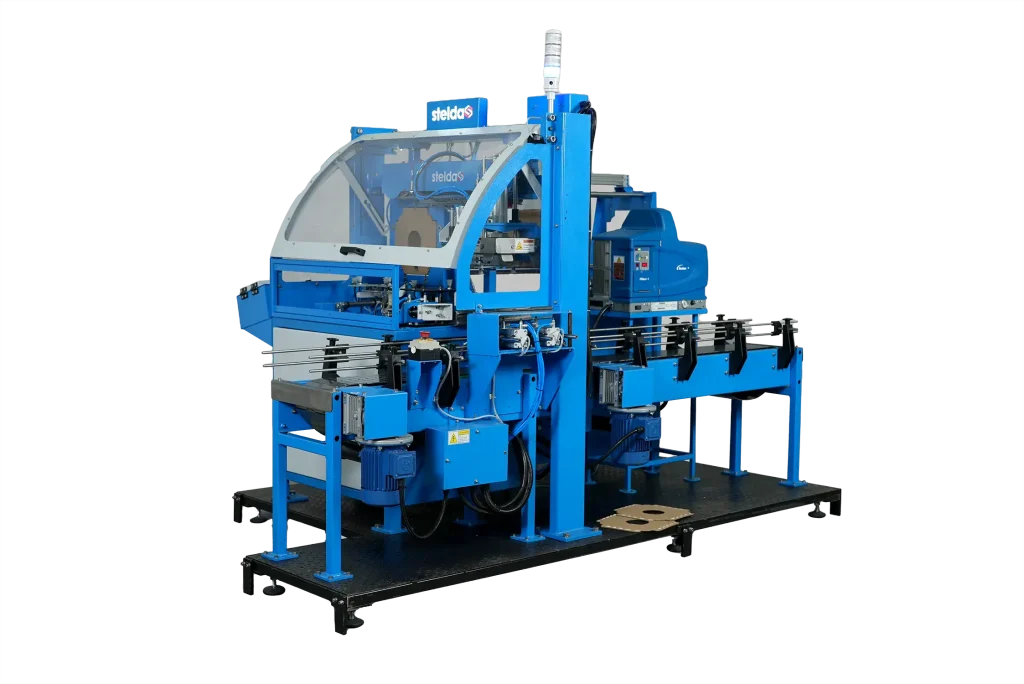

STELDA TCP 15

Automate your packaging line with precision gluing and seamless integration for 15-liter oil tins.

The STELDA TCP 15 is a state-of-the-art Automatic Cap Placer designed for 15-liter oil tins. Built for precision and efficiency, this machine seamlessly integrates with oil filling lines to ensure synchronized operation.

- Non-Stop Operation: Handles continuous feeding and Cap placement.

- Precision Gluing: Utilizes Nordson® technology for clean and secure seals.

- High-Speed Performance: Achieves up to 15 tins per minute, matching line speeds for maximum efficiency.

Detailed Specifications of the STELDA TCP 15

Model

TCP 15

Mode

Hot Melt Glue

Working Speed

15 Tins / minute

Feature

Specification

Size of the Box

240mm (L) X 240mm (W) X 325mm (H)( +/- 3mm)

Gluing System & Taping Head

Nordson System

Magazine Infeed Capacity

600 collars (standard)

Electrical Requirement

3 Phase, 440V, 50 Hz, 7 kW

Air Pressure Requirement

15 CFM, 6 Bar (Dry Air)

Machine Dimensions

2760mm (L) X 1680mm (W) X 1739mm (H)

Machine Standards

Our machines are CE compliant & ISO:9001 certified. STELDA packaging systems come with Nordson® Industrial Gluing Nozzles controlled by SMART CONTROL SYSTEMS for on-demand gluing using temperature controlled adhesives to maintain adhesion consistency.

Why Choose the STELDA TCP 15?

Servo-Controlled Pick and Place

Dual-arm technology ensures accurate Cap placement.

Nordson® Gluing System

Precision gluing with synchronized linear nozzle movement.

Real-Time Monitoring

Tracks operational performance to minimize downtime.

Safety First

Incorporates advanced human safety features, including interlocked guarding.

Energy Efficiency

Optimized adhesive application reduces glue wastage.

Customizable Layouts

Flexible designs to fit your specific operational requirements

What Our Clients Say About the TCP 15

Experience the

STELDA TCP 15

Contact Us for Pricing and

Custom Solutions

Frequently Asked Questions About The STELDA TCP 15

1. What is the maximum tin size supported?

The STELDA TCP 15 supports oil tins with dimensions of 240x240x320mm (LxWxH).

2. How does the gluing system ensure precision?

The Nordson® gluing system features synchronized linear nozzle movement for accurate adhesive application and tamper-evident seals

3. Can the machine be customized to fit my operational layout?

Yes, the STELDA TCP 15 is an Automatic Cap Placer which offers flexible layout configurations to suit your specific packaging line requirements.