Henkel India moves to Stelda’s Hotmelt Case Sealing for a Smarter, Sustainable Future.

Henkel Adhesive Technologies India, the world leader in adhesives, recently achieved a remarkable milestone in sustainable packaging — and the driving force behind it? Stelda’s Hotmelt Case Sealing Automation system.

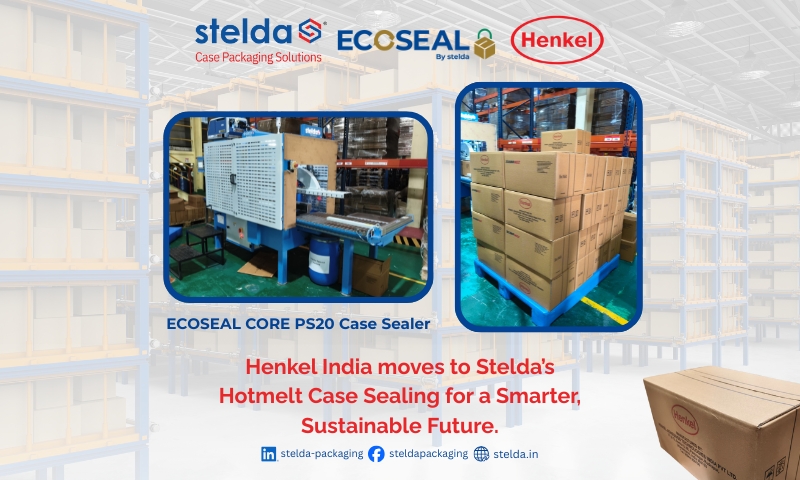

Let’s dive into the inspiring journey of how Henkel, a global adhesive giant, transformed its packaging lines using Stelda ECOSEAL CORE: PS20 Case Sealer — a custom-engineered innovation that not only sealed cartons but also sealed Henkel’s commitment to sustainability, efficiency, and excellence.

Henkel’s Unique Edge — A Global Adhesive Pioneer

Henkel stands tall as a world leader in adhesive manufacturing. The company’s innovative spirit goes beyond bonding materials — it bonds innovation with sustainability. Their core mission? To make packaging smarter, cleaner, and more sustainable.

One of their standout achievements lies in reducing GSM (grams per square meter) — effectively lightweighting cartons without compromising strength or durability. This not only cut down material costs but also supported their long-term sustainability vision.

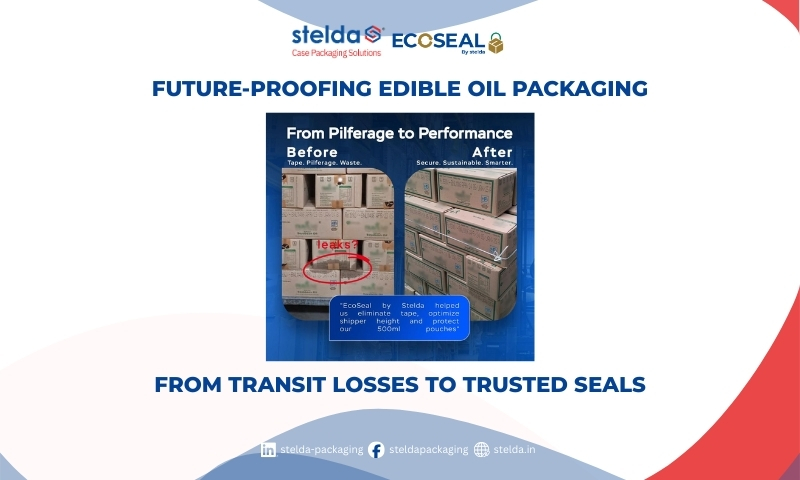

Another game-changing initiative was the elimination of BOPP tapes, replacing them with glue-sealed shippers — a move that significantly reduced single-use plastic waste.

“One of our biggest customers in hygiene care accepted glue-sealed shippers instead of BOPP tapes,” shared Henkel proudly.

That single decision changed the trajectory of packaging practices for one of the world’s top hygiene brands — and it began right here at Henkel’s Pantnagar facility.

About Henkel Adhesive Technologies India

At Henkel Adhesive Technologies India Pvt. Ltd., innovation isn’t just about better adhesives — it’s about rethinking every layer of performance, including packaging.

Recently, at their Pantnagar plant (Rudrapur, Uttarakhand), Henkel implemented the Stelda ECOSEAL CORE PS20HM — a fully automated Hotmelt Case Sealer engineered for reliability, efficiency, and sustainability.

The Stelda Solution: ECOSEAL CORE PS20 Case Sealer

To match Henkel’s vision of eco-efficient packaging, Stelda customized its cutting-edge ECOSEAL CORE: PS20 Case Sealer with Hotmelt Adhesive technology and an integrated box pusher assembly.

This was not just a machine; it was a collaboration of innovation and purpose. 💡

Key Highlights of Stelda’s Hotmelt Case Sealing Automation:

- Tamper-Evident Sealing – Protects packaging integrity during transit.

- Top & Bottom Sealing – Enhances palletizing and ensures consistent stability.

- Nordson® Hotmelt System – Advanced adhesive control for perfect, uniform seals.

- High-Speed Performance – Processes up to 20 cases per minute (CPM) effortlessly.

- Single Operator Friendly – Simplified control, reducing manpower needs.

- Eco-Efficient Design – Cuts corrugate use, eliminates plastic tapes, and supports sustainability.

- Built for Global Safety – Complies with international safety standards for continuous operation.

- Long-Lasting Seals – Ideal for extended storage and export-ready shipments.

- Optional Add-ons – Cold glue/tape sealing, box centralizing, and feed-in conveyors for higher line efficiency.

In Henkel’s setup, this smart automation has delivered zero-gap sealing, cleaner shippers, and higher productivity — proving that Hotmelt Case Sealing Automation is not just efficient but future-ready.

A Collaboration That Defined Excellence

Stelda’s role went beyond providing equipment, It became a strategic partner in Henkel’s sustainability journey.

“Stelda is helping us achieve our sustainability goals by eliminating the use of single-use plastic and reducing paper consumption,” shared Henkel’s team.

With continuous technical support and optimization, Stelda ensured seamless integration into Henkel’s high-performance manufacturing environment.

Their technical support was rated excellent by the Henkel team, reflecting not just equipment reliability but a partnership rooted in shared vision and trust.

Proud Moments: Milestones That Matter

Henkel and Stelda’s collaboration produced milestones that reshaped packaging norms:

Achievements:

- ✅ Reduction of GSM: Lightweight cartons with the same durability and protection.

- ✅ Elimination of BOPP Tapes: Transitioned to 100% adhesive-based sealing.

- ✅ Enhanced Efficiency: Faster sealing with minimal maintenance downtime.

- ✅ Cleaner Aesthetics: Shippers now look sleek, uniform, and professional.

These upgrades not only improved product protection but also elevated Henkel’s sustainability scorecard across its packaging lines.

Proud Association — Supplying to P&G

Among the projects that Stelda holds closest to its heart is the successful delivery of adhesive-sealed shippers to P&G.

This achievement stands as a testament to how the right technology and partnership can redefine packaging standards for global brands.

By implementing Hotmelt Case Sealing Automation, Henkel and Stelda together set new benchmarks for packaging integrity, product hygiene, and environmental responsibility.

Final Takeaway: The Future is Sealed with Purpose

The Henkel–Stelda collaboration reminds us that the real power of packaging lies not in materials, but in mindset.

Together, they’ve proven that automation, innovation, and sustainability are not separate goals — they’re part of one unified future.

If you’re looking to transform your packaging line into a cleaner, faster, and greener operation, now is the time to act.

👉 Follow Stelda on LinkedIn, Instagram, and YouTube for more real-world stories, packaging innovations, and sustainability insights.

Let’s seal a better tomorrow, together. 💚