In today’s world, sustainability is more than a buzzword — it’s a global movement.

For Abar Water, one of Saudi Arabia’s leading bottled water companies, it became a mission that reshaped their packaging line forever. Abar Hail Water has enjoyed international quality for drinking water since 2008. During these years, Abar Hail Water Company has managed to become one of the leading companies in the field of drinking water bottling.

They wanted to move beyond single-use plastic and embrace eco-friendly automation without sacrificing productivity.

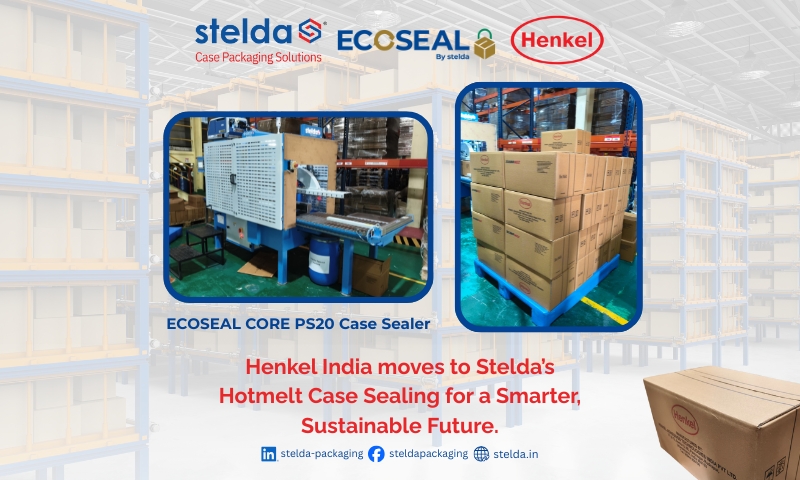

That’s when the ECOSEAL CORE PS20 HM Case Sealer came into play — a powerful partner in achieving packaging sustainability efficiency.

The Challenge: Breaking Free from Single-Use Plastic

Every great transformation begins with a bold goal.

For Abar Water, it was clear:

“We wanted to eliminate single-use plastic and move toward sustainable packaging.”

As one of the top names in drinking water bottling, Abar Water was aware of the environmental impact of traditional sealing methods.

But sustainability couldn’t come at the cost of speed, accuracy, or performance.

They needed a solution that could balance green goals with operational efficiency — and Stelda delivered just that.

The Turning Point: Choosing Stelda for a Greener Tomorrow

When Abar Water discovered ECOSEAL CORE PS20 HM, they saw more than just a case sealer.

They saw a path toward sustainable growth.

Their decision was driven by one powerful vision:

“To meet our sustainability goal.”

The ECOSEAL CORE PS20 HM offered the perfect blend of automation, innovation, and environmental responsibility, redefining what efficiency means in modern packaging.

The Impact: Efficiency Meets Sustainability

The results spoke louder than words. After introducing the ECOSEAL CORE PS20 HM Case Sealer, Abar Water witnessed an impressive transformation across its production line.

Here’s how they achieved packaging sustainability efficiency:

- Operational Efficiency: Streamlined sealing reduced bottlenecks and improved output.

- Increased Productivity: Higher throughput with consistent, reliable performance.

- Time & Manpower Savings: Automation reduced manual dependency and improved worker safety.

- Eco-Friendly Packaging: No more plastic tapes — just strong, glue-based, sustainable sealing.

And when asked which feature stood out most?

“Auto Flap Closer — most valuable feature.”

This innovative system ensured that every carton was sealed automatically, reducing manual errors while optimizing sustainability and workflow.

Behind the Innovation: How ECOSEAL CORE PS20 HM Powers Green Efficiency

The ECOSEAL CORE PS20 HM Case Sealer isn’t just an automation tool — it’s a sustainability enabler.

Here’s what makes it an industry favorite:

- 🔹 Hot Melt Gluing Technology: Eliminates single-use plastic tape, ensuring eco-friendly sealing.

- 🔹 Smart Automation: Seamlessly integrates flap closing and sealing in one automated motion.

- 🔹 Energy-Efficient Design: Consumes less power while maximizing performance.

- 🔹 Precision Engineering: Guarantees consistent, durable sealing for every carton.

- 🔹 Reduced Waste: Creates cleaner, neater seals that enhance brand presentation.

In short, it’s technology that cares — for both productivity and the planet. 🌍

Abar Water’s Verdict: A Perfect Blend of Support and Innovation

When it comes to customer satisfaction, Abar Water couldn’t be happier.

On being asked about their experience, they rated Stelda’s technical support as:

“Excellent.” It’s not just about selling a machine — it’s about building long-term partnerships that drive progress.

And yes, they would absolutely recommend Stelda to other businesses seeking packaging sustainability efficiency.

Beyond Packaging — Towards a Sustainable Future

The partnership between Abar Water and Stelda reflects a new era in the packaging industry — where efficiency and sustainability coexist.

By integrating the ECOSEAL CORE PS20 HM Case Sealer, Abar Water:

- Eliminated plastic tape usage.

- Reduced environmental waste.

- Enhanced production performance.

- Strengthened their sustainability footprint.

Their success proves that when innovation meets purpose, great things happen.

The Ripple Effect: Inspiring the Industry to Go Green

Abar Water’s transformation has become a benchmark for the beverage and FMCG industries.

Their success story demonstrates how sustainability doesn’t have to come at the expense of performance — in fact, it can amplify it.

With packaging sustainability efficiency, businesses can now embrace both growth and green responsibility.

The Takeaway: The Future is Efficiently Sustainable

At Stelda, every innovation is built around one principle — efficiency with responsibility.

The Abar Water journey proves that the future of packaging isn’t just about speed or cost — it’s about purpose-driven performance.

If your brand wants to enhance efficiency, eliminate plastic, and move towards a greener future —

👉 Explore Stelda’s Packaging Sustainability Efficiency solutions today.

Follow us for more real-world success stories, sustainability insights, and automation breakthroughs.

#SteldaPackaging #PackagingSustainabilityEfficiency #SustainablePackaging #AbarWater #HotMeltGluing #AutomationForGood #GreenManufacturing #FutureReady #EcoFriendlyPackaging #SmartAutomation #EfficiencyMeetsSustainability #SteldaSolutions #PackagingInnovation