Dr. Reddy’s Laboratories (DRL), one of India’s leading pharmaceutical manufacturers, has always placed a strong emphasis on quality, compliance, and traceability across its production facilities. As a company catering to highly regulated markets like the US and Europe, DRL’s manufacturing lines are expected to maintain the highest levels of data integrity and accuracy — especially in packaging and labeling processes.

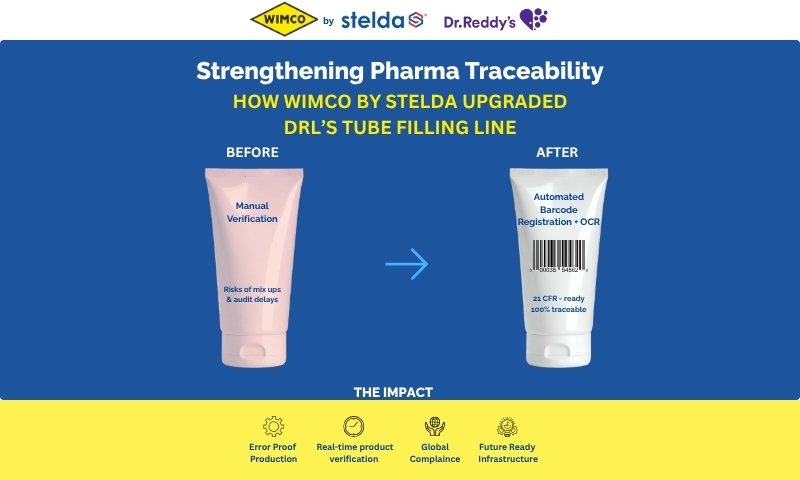

To strengthen their compliance framework and eliminate the risk of product mismatch or labeling errors, DRL partnered with WIMCO by Stelda to upgrade their existing WIMCO GAN 120 tube filling machine. The goal was to enhance the line’s pharma traceability and verification systems through the integration of barcode registration and Optical Character Recognition (OCR) technology — a crucial step toward pharma traceability with barcode registration and OCR compliance.

The Challenge

Pharmaceutical packaging demands absolute precision and traceability. For DRL, the key challenges were:

- Ensuring correct product identity at the filling stage — avoiding any chance of mixing or mislabeling.

- Meeting stringent international traceability standards, particularly those required for export to regulated markets.

- Maintaining production efficiency while introducing new verification systems.

- Reducing dependency on the legacy iMark (black strip) system, which offered limited traceability and no data recording capability.

The existing GAN 120 line, though reliable, lacked an automated system for barcode verification and OCR scanning — features essential for 21 CFR compliance and error-proof product release in the pharma traceability domain.

The WIMCO by Stelda Solution

The engineering and automation team at WIMCO by Stelda worked closely with DRL to retrofit their WIMCO GAN 120 machine with advanced barcode registration technology, transforming it into a digitally traceable, compliance-ready line and setting a new benchmark in pharma traceability with barcode registration and OCR integration.

1. Barcode Registration System

The first major upgrade was the installation of a barcode registration system that replaced the traditional iMark black strip.

- Functionality: Each tube now carries a unique product barcode that is scanned and verified at the filling station.

- Purpose: The system ensures that only the correct product is processed — preventing mix-ups and wrong product dispatches.

- Compliance: This aligns with DRL’s need for serialized product tracking as per global pharma norms.

- Outcome: The barcode system provides real-time verification and ensures that every tube is linked to the correct batch data in the system’s records.

This marks a significant shift from a mechanical registration system to a smart, data-driven verification platform, offering both accuracy and audit-ready digital documentation.

2. Optical Character Recognition (OCR) Integration (Work in Progress)

Building on the success of barcode registration, WIMCO by Stelda initiated the integration of an OCR system designed to read expiry dates and batch codes printed on the tube seal.

- Functionality: OCR will automatically capture and verify printed information on every tube, ensuring no mismatch between physical print and batch data.

- Future Advantage: Once implemented, it will enable dual-level validation — barcode for product identity and OCR for batch & expiry data — thereby achieving end-to-end pharma traceability.

This stage is still under progress, as DRL and WIMCO by Stelda collaborate to fine-tune OCR’s accuracy and ensure seamless synchronization with DRL’s production data systems.

Ensuring Clean Changeovers and Product Integrity

Given DRL’s multiple SKUs and strict cross-contamination policies, WIMCO by Stelda also aligned its machine cleaning protocols with pharma-grade practices.

The filling pumps, nozzles, and tubing systems are designed for quick disassembly and autoclave sterilization, minimizing downtime during product changeovers while maintaining hygiene and regulatory standards.

Impact and Benefits

The barcode registration upgrade delivered measurable improvements in DRL’s production and compliance processes:

| Aspect | Before Upgrade | After WIMCO by Stelda Upgrade |

| Product verification | Manual / visual | Automated via barcode scanner |

| Traceability | Limited | Digital, data-linked |

| Risk of mix-up | Possible during multi-SKU runs | Eliminated with barcode control |

| Data recording | Manual logs | Automated system logs |

| Compliance readiness | Partial | Ready for 21 CFR and export compliance |

Additional benefits include:

- Faster batch release through automated verification logs.

- Error-free packaging for global markets.

- Reduced operator dependency and improved process reliability.

- Future-ready infrastructure for OCR and serialization expansion.

Conclusion

The DRL– WIMCO by Stelda collaboration exemplifies how targeted automation upgrades can transform legacy equipment into 21 CFR-ready, traceability-compliant systems without complete line replacement.

By replacing iMark with a barcode registration system, and moving toward OCR-based verification, WIMCO by Stelda has enabled DRL to achieve error-proof production, digital traceability, and global compliance confidence — a milestone in pharma traceability with barcode registration and OCR innovation.

This project reinforces WIMCO by Stelda’s position as a trusted automation partner in the pharmaceutical packaging industry — combining mechanical excellence with digital intelligence to help clients stay ahead in regulatory readiness and operational precision.

Meet us at Stall RH.K70, PMEC India 2025 and explore how to upgrade your existing line for traceability, speed & compliance.