✨ What happens when sealing innovation meets niche expertise in edible oil packaging?

At Anuga Food Tec 2025, STELDA is set to showcase its powerful ECOSEAL range of sealing machines, including the newly launched TCP 15 for edible oil lines — co-presented alongside our edible oil systems partner Spheretech Packaging India Pvt Ltd.While each brand operates independently, we are sharing the stage to demonstrate complementary innovations that together enhance performance in edible oil packaging.

🤝 STELDA x Spheretech – A Strategic Collaboration

STELDA and Spheretech are joining forces at Anuga Food Tec 2025 to present a unified vision for edible oil industry solutions. While each brand brings its own expertise, the goal is common: to help businesses scale with speed, security, and sustainability.

What you can expect from this event:

- A combined product showcase that addresses every touchpoint in the secondary and primary packaging line

- Seamless integration of sealing, filling, and capping technologies

- Insight into the latest advances in tamper-evident sealing and high-accuracy dosing

📦 Product Spotlight – What’s On Display?

🔵 ECOSEAL BY STELDA’s Smart Sealing Machines

ECOSEAL TCP 15 — Cap Sealing That Keeps Up With Your Line

Built for 15-litre oil tins, the TCP 15 brings seamless automation and precision gluing to your edible oil packaging line. Presented in collaboration with Spheretech for Edible Oil Lines, designed for 15-litre tins, the TCP 15 seamlessly integrates into edible oil lines powered by Spheretech’s liquid filling and capping systems. This collaborative presentation at Anuga highlights how precise gluing complements high-speed filling, enabling manufacturers to optimize both speed and shelf security.

- Non-stop precision placement: Dual-arm servo system ensures accurate and consistent cap placement at high speeds — up to 15 tins per minute.

- Clean, controlled gluing: Powered by Nordson® nozzles, the hot melt glue system delivers tamper-evident seals without excess adhesive.

- Real-time system monitoring: Operators can track performance and minimize downtime through intelligent control interfaces.

- Built for scale and safety: CE-compliant, ISO:9001 certified, and designed with interlocked safety guards for smooth industrial use.

- Flexible integration: With a compact footprint and customizable layouts, it fits neatly into diverse oil-filling lines.

🟩 ECOSEAL CE 6T — Smart Case Forming Without the Bulk

The STELDA CE 6T is a compact case erector built for businesses that want speed, safety, and simplicity in one space-saving unit.

- Space-smart design: With a small footprint and castor wheels, it fits easily into tight production zones and moves when you need it to.

- Hands-free case forming: Vacuum-assisted opening ensures precise case erecting — no jams, no manual struggle.

- Plug-and-play ease: Switch between case sizes quickly with minimal effort, perfect for varied SKUs and fast-moving setups.

- Built-in intelligence: Advanced PLC controls and an MIS system offer real-time production insights and simple troubleshooting.

- Safety-first operation: Global safety compliance and interlocked guarding make it reliable for 24/7 industrial use.

ECOSEAL Machine Launch at Anuga FoodTec 2025

STELDA will launch its ECOSEAL range of sealing machines at Anuga FoodTec 2025 — with a special focus on ECOSEAL Ready, a future-forward taping system designed for packaging lines that aren’t glue-ready yet. Built for businesses that want reliability today and flexibility tomorrow, ECOSEAL Ready delivers clean, consistent seals and offers a seamless upgrade path to hot-melt glue sealing when the time is right.

🟩 ECOSEAL READY — Tape Today, Glue Tomorrow

The ECOSEAL READY is a future-forward sealing machine built for businesses that want the flexibility to evolve.

- Starts with tape, built for glue: Currently a tape sealing system — but fully upgradeable to hot-melt glue when you’re ready to scale up.

- Cleaner closures, ready shelves: Delivers uniform seals that enhance shelf readiness and reduce tampering risks.

- Minimal downtime: Designed for continuous operation with fewer stoppages and consistent performance.

- Adaptable design: Ideal for businesses exploring a shift from conventional tape to more sustainable gluing options.

- Scalable sealing made easy: A machine that grows with your packaging goals — from startup mode to enterprise-ready.

From Spheretech: Liquid Filling & Capping Systems

SphereTech Liquid Nitrogen Doser — Freshness Sealed in Every Drop

The LN2 Doser from SphereTech ensures product longevity, container stability, and production efficiency — all in one ultra-precise dosing solution.

- Keeps products fresh, longer: Creates a nitrogen-rich headspace that slows oxidation and preserves product integrity from line to shelf.

- Boosts shelf stability: Stabilizes containers by equalizing internal pressure — especially vital for lightweight or PET bottles.

- Incredibly efficient: Uses minimal LN2 with ultra-low loss, helping you save on resources while staying sustainable.

- Hygiene-friendly design: Engineered with smooth, wash-down-ready surfaces that make cleaning effortless and downtime minimal.

- Compact & compatible: Easy to integrate across production lines, whether you’re working with liquids, powders, or hot fill applications.

💡 What Makes These Smarter Packaging Solutions Different?

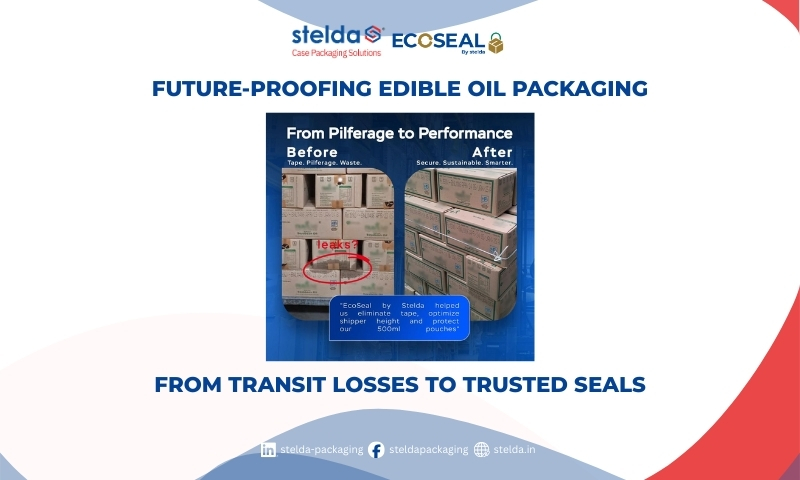

🔹 Tamper-Evident Security by Design

No more relying on tape or flimsy stickers. STELDA’s ECOSEAL locks carton fibers—if it’s been opened, it shows. This is especially critical for food exports and pharma compliance.

🔹 Flexibility in Production

Whether it’s random carton sizes or varying fill grammages, these machines adapt without lengthy changeovers. You save time, reduce downtime, and improve output.

🔹 Data & Efficiency Monitoring

Live dashboards show glue usage, energy consumption, production metrics—so you know where to optimize in real time.

🔹 Reduced Environmental Impact

By removing wastage, both brands help reduce your operation’s carbon footprint.

📍 H2: Visit Us at Anuga Food Tec 2025

📍 Hall 4 | Booth L 22

Join STELDA and Spheretech at the most influential event in food and beverage processing and packaging technology.

At the booth, you’ll:

✅ Experience live demos of sealing, filling, and capping automation

✅ Get personalized consultations on integrating these technologies into your existing line

✅ Discover how you can improve quality, speed, and compliance—without increasing costs

🔚 Where Technology Meets Value

Whether you’re a food manufacturer, exporter, or contract packer, you’ll find tools here to take your packaging line to the next level.

👉 Want to see it in action?

Register now to meet our teams at Anuga Food Tec 2025 and explore how we can customize a packaging solution that fits your needs—today and tomorrow.

#AdvancedPackagingSolutions #STELDA #Spheretech #AnugaFoodTec2025 #PackagingInnovation #SmartSealing #LiquidFilling #SustainablePackaging #AutomationThatWorks #NoMoreTapes #EcoSeal #HotMeltGlue #B2BPackaging #ExportPackaging #FutureReadyPackaging