WIMCO by Stelda at PMEC India 2025

We’re excited to announce that WIMCO by Stelda will be showcasing its latest tube filling innovations at PMEC India 2025, from 25th to 27th November 2025 at the India Expo Center, Greater Noida, Delhi NCR.

Visit us at Stall No. RH.K70 and explore end-to-end packaging solutions – from primary to secondary and tertiary packaging — tailored for the pharma, cosmetics, and healthcare sectors.

At our booth, you’ll witness WIMCO’s engineering precision come alive through solutions like the GAN 120 Tube Filling Machine and the PAC 120 Cartoning Machine, both built to deliver performance, reliability, and compliance in high-demand production environments.

About WIMCO: A Legacy of Engineering Excellence

WIMCO has been a trusted name in packaging machinery for decades, known for its robust build quality, precision, and consistent performance.

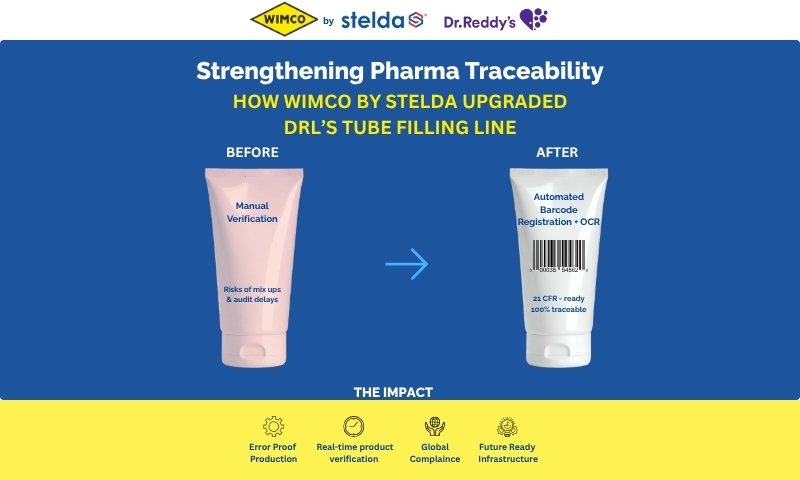

Now integrated under Stelda Case Packaging Solutions, WIMCO continues to push boundaries by combining proven mechanical reliability with smart automation and advanced controls.

The GAN 120 exemplifies this blend — a high-speed, accurate, and adaptable double head tube filling solution ideal for pharmaceutical and personal care products. Complementing it, the PAC 120 Cartoning Machine ensures seamless integration from primary to secondary packaging, offering compact design, flexibility, and quick changeovers.

Together, they represent WIMCO’s commitment to delivering complete packaging solutions, all under one roof.

Why Attend PMEC India 2025?

PMEC India is South Asia’s most influential exhibition for pharmaceutical machinery and packaging innovation, connecting global technology providers and manufacturers.

Here’s why it’s a must-attend event:

- 🌍 Network with global pharma and packaging leaders

- ⚙️ Experience live machinery demos including high-speed tube filling and cartoning systems

- 💡 Discover automation upgrades that improve productivity and compliance

- 🧭 Stay updated on 21 CFR, GMP, and serialization trends

Whether you’re exploring modernization, cost-efficiency, or sustainability, PMEC India 2025 is where innovation meets opportunity.

Product Showcase: Precision Meets Performance

🔹 GAN 120 – High-Precision Tube Filling Machine

The WIMCO GAN 120 is engineered for high-speed precision filling, delivering speeds of up to 120 tubes per minute. Its adaptable design supports laminated, plastic, and aluminum tubes, making it ideal for pharmaceutical, cosmetic, food, and chemical industries that handle diverse viscosity ranges and high-output demands.

Key Highlights:

- Tail-Free Filling:

Ensures zero product wastage, maintaining the highest standards of efficiency. - Versatile Sealing Options:

Equipped with a combination sealer for laminated, plastic, and aluminum tubes. - Proven Performance:

Features a hot air sealing system for plastic and laminated tubes, ensuring consistent reliability. - Quick Changeovers:

Simplifies adjustments between different tube sizes and materials for maximum uptime. - Durable Design:

Centralized lubrication reduces maintenance needs while improving machine longevity.

The GAN 120 represents the best of WIMCO’s engineering — a blend of accuracy, speed, and adaptability for dynamic production environments.

🔹 PAC 120 – Automatic Cartoning Machine

The WIMCO PAC 120 is designed to deliver unmatched packaging speed, accuracy, and flexibility across diverse industries. With cutting-edge automation and precision engineering, it ensures high throughput, minimal downtime, and absolute reliability.

Key Highlights:

- Speed & Efficiency:

Achieves optimum speeds of 120–140 cartons per minute for faster production cycles. - Quick Changeovers:

Enables seamless transition between products and carton sizes for continuous production. - Advanced Automation:

Includes automatic leaflet insertion and intelligent systems such as:

No Product–No Carton–No Leaflet–No Carton to ensure zero errors. - Energy-Efficient Design:

Integrated variable frequency drive (VFD) ensures low power consumption. - High Reliability:

Features a centralized lubrication system for enhanced machine longevity. - Built for Compliance:

Fully adheres to GMP and CE standards, making it ideal for regulated pharmaceutical environments.

With carton handling dimensions of 18–84 mm (breadth), 18–50 mm (height), and 85–215 mm (length), the PAC 120 integrates seamlessly with tube filling and case packaging systems, offering a complete, connected solution.

WIMCO’s TubeFill Care+ Programme: Upgrade. Maintain. Future-Proof.

At PMEC India 2025, WIMCO will be showcasing TubeFill Care+ Programme — a complete service, audit, and upgrade initiative designed to extend the life and performance of your tube filling machines.

Here’s what you can expect:

🩺 Free Machine Health Check-Up

🔧 Expert Audit & Technical Consultation

💰 Affordable Spare Parts Packages

⚙️ Upgrade Your WIMCO Machine with Smart Enhancements

Transform your legacy system with the latest innovations:

- Cam-to-Servo Conversion – for smoother motion control

- Pneumatic Sealing & Trimming Systems – enhanced precision and reliability

- Contactor-Relay to PLC-Based Control Upgrade – smart, digital automation

- Metal/Laminated Tube to Combination Machine – flexibility for multi-material use

- 21 CFR Compliance – meet global pharma standards effortlessly

The TubeFill Care+ Programme ensures your WIMCO system remains efficient, compliant, and production-ready for years to come.

Visit WIMCO by Stelda at PMEC India 2025

📍 Venue: India Expo Center, Greater Noida, Delhi NCR

📅 Date: 25th – 27th November 2025

🧭 Stall No.: RH.K70

Join us for live demonstrations of WIMCO’s GAN 120 Tube Filling Machine and PAC 120 Cartoning Machine, alongside expert consultations on TubeFill Care+ upgrades and integrated packaging solutions.

✨ From precision tube filling to automated cartoning and case packaging — experience the future of packaging automation with WIMCO by Stelda.

👉 Explore. Upgrade. Transform.

Your complete packaging partner, from tube to case.

🔗 Stay Connected:

LinkedIn: stelda-packaging | Facebook: steldapackaging | Website: stelda.in